Dareemka booska Crankshaft

Tusmo

Dareemka crankshaft wuxuu bixiyaa xakamaynta mishiinka ECU ee booska qaybta farsamada ee ka masuulka ah hawlgalka nidaamka durida shidaalka. Marka DPKV uu fashilmo, waxaa lagu ogaadaa iyadoo la kaashanayo tijaabiyeyaal gaar ah oo ku shaqeynaya mabda'a ohmmeter. Haddii ay dhacdo in qiimaha iska caabbinta hadda uu ka hooseeyo qiimaha magaca, beddelka koontaroolaha ayaa loo baahan doonaa.

Maxaa ka mas'uul ah sideese u shaqeeyaa dareemaha dareemaha crankshaft?

Dareemka booska crankshaft ayaa go'aamiya sida saxda ah marka shidaalka loo diri doono matoorka gubashada gudaha (ICE) dhululubada. Naqshado kala duwan, DPKV ayaa mas'uul ka ah xakamaynta hagaajinta isku mid ahaanshaha sahayda shidaalka ee cirbadaha.

Hawlaha dareemayaasha crankshaft waa in la diiwaan geliyo oo u gudbiyo xogta soo socota kombiyuutarka:

- cabbir booska crankshaft;

- daqiiqada pistons-ku dhaafaan BDC iyo TDC ee dhululubada hore iyo kan ugu dambeeya.

Dareemaha PKV wuxuu saxaa tilmaamayaasha soo socda:

- xaddiga shidaalka soo galaya;

- waqtiga bixinta shidaalka;

- xagasha camshaft;

- waqtiga dabka;

- daqiiqad iyo muddada hawlgalka ee waalka adsorption.

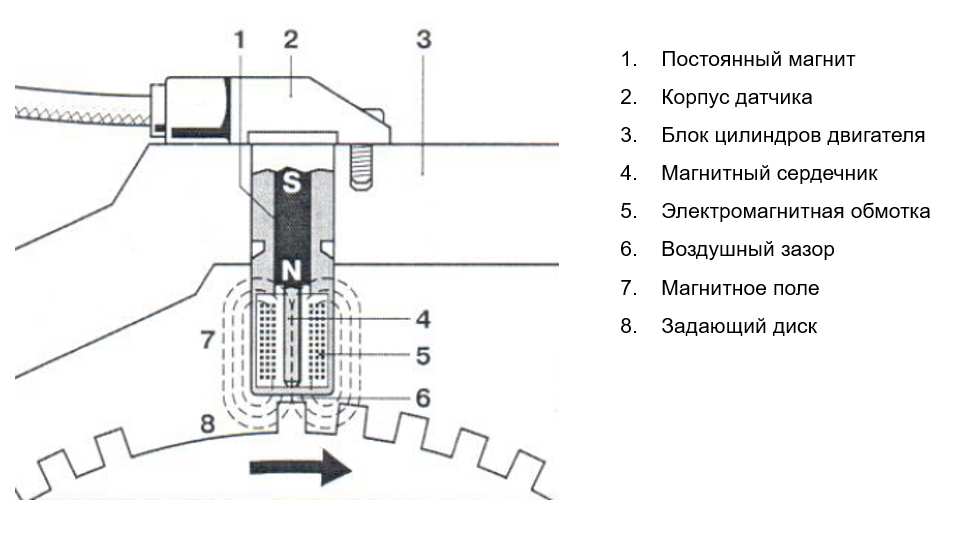

Mabda'a hawlgalka dareenka wakhtiga:

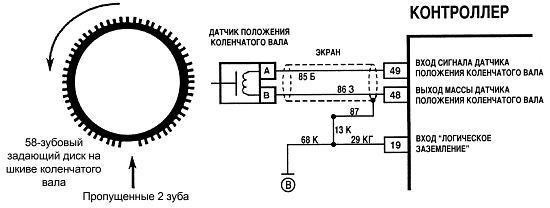

- Qalabku waxa uu ku qalabaysan yahay saxan ilko leh (bilaw iyo eber). Marka shirku wareego, goobta birlabku waxay u jihaysan tahay ilkaha laga bilaabo dareeraha PKV, isaga oo ku dhaqmaya. Isbeddelada waxaa loo diwaangeliyaa qaabka garaaca, macluumaadkana waxaa loo gudbiyaa kombuyuutarka: booska crankshaft waa la cabbiraa iyo marka pistons ay maraan xarumaha sare iyo kuwa hoose ee dhintay (TDC iyo BDC) waa la duubayaa.

- Marka sprocket-ku uu dhaafo dareemaha xawaaraha crankshaft, waxa uu beddelaa nooca akhriska kobcinta. Sababtan awgeed, ECU waxay isku dayeysaa inay dib u soo celiso hawlgalkii caadiga ahaa ee shafka.

- Iyada oo ku saleysan garaaca wadnaha la helay, kumbuyuutarka dusha sare wuxuu u diraa calaamada nidaamyada gaadiidka lagama maarmaanka ah.

Qalabka DPKV

Naqshadeynta dareemayaasha Crankshaft:

- kiis aluminium ama caag ah oo leh qaab cylindrical ah oo leh curiye xasaasi ah, kaas oo calaamada loo diro kombiyuutarka;

- fiilada isgaarsiinta (wareegga magnetic);

- qaybta wadista;

- shaabadaysan;

- dabaylaha;

- giraanta matoorka.

Shaxda: noocyada dareemayaasha

| magaca | Description |

| Dareemaha magnetic

| Dareemuhu wuxuu ka kooban yahay birlab joogto ah iyo dabaysha dhexe, koontaroolaha noocaan ah uma baahna sahay koronto oo gooni ah. Qalabka koronto-dhaliyaha ah ayaa xakameynaya ma aha oo kaliya booska crankshaft, laakiin sidoo kale xawaaraha. Waxay la shaqeysaa danab ku dhaca marka ilig bir ah (tag) uu dhex maro goob birlab ah. Tani waxay dhalinaysaa garaaca garaaca wadnaha oo taga ECU. |

| Dareemayaasha indhaha

| Dareemka indhaha wuxuu ka kooban yahay qaataha iyo LED. La falgalka saxanka saacadda, waxay xannibaysaa socodka indhaha ee u dhexeeya aqbalaha iyo LED-ka. Gudbiyuhu waxa uu ogaadaa kala goynta iftiinka. Marka LED-ku uu dhex maro aagga ilko duugoobay, qaataha waxa uu ka falcelinayaa garaaca garaaca oo waxa uu la shaqeeyaa ECU. |

| Hoolka dareeraha

| Naqshadeynta dareemayaasha waxaa ka mid ah:

Saamaynta Hall-ka dareemaha crankshaft, hadda wuu socdaa marka uu ku soo dhawaado goobta magnetic beddelka. Wareegga goobta xoogga ayaa furmaya marka la dhex maro aagagga leh ilko duugoobay iyo calaamadda waxaa loo gudbiyaa qaybta kontoroolka matoorka elektaroonigga ah. Ka shaqeeya ilo koronto oo madax banaan. |

Xagee ku yaalaa dareemaha?

Goobta dareemaha booska crankshaft: oo ku xigta saxanka u dhexeeya jilbaha beddelka iyo duuliyaha. Isku xirka bilaashka ah ee shabakadda guddiga, fiilo dhererkeedu yahay 50-70 cm ayaa la bixiyaa, kaas oo ay ku jiraan xirayaasha furayaasha. Waxaa jira meelo bannaan oo korreeya si ay u dejiyaan farqiga 1-1,5mm.

Astaamaha iyo sababaha cillad -darrada

Calaamadaha DPKV jabay:

- matoorku ma bilaabo ama si kedis ah uma istaago muddo ka dib;

- dhimbiil la'aan;

- Qarxinta ICE waxay ku dhacdaa xilliyada qaar culeysyo firfircoon;

- Xawaaraha aan shaqaynayn;

- awoodda injiinka iyo dhaqdhaqaaqa baabuurta ayaa la dhimay;

- marka la beddelo hababka, isbeddel lama filaan ah oo tirada kacdoonnada ayaa dhacaya;

- hubi iftiinka injiinka ee dashboard-ka.

Calaamaduhu waxay tilmaamayaan sababaha soo socda sababta dareemaha PCV-gu uu cilladaysan yahay:

- wareeg gaaban oo u dhexeeya leexashada dabaysha, dhalanrog suurtagal ah ee calaamada ku saabsan booska piston ee BDC iyo TDC;

- fiilada ku xidhaysa DPKV iyo ECU waa dhaawac gaadhay - kombayuutarka dusha saarani ma helo wargelin habboon;

- cilladda ilkaha (scuffs, chips, dildilaac), matoorku ma bilaabi karo;

- Soo galitaanka walxaha shisheeye ee u dhexeeya jiidaha ilka leh iyo miiska ama dhaawaca inta lagu jiro shaqada qaybta matoorka waxay badanaa keentaa cillad DPKV ah.

Dhibaatooyinka bilaabista mishiinka

Kala duwanaanshaha cilladaha dareemaha crankshaft ee saameeya shaqada matoorka gubashada gudaha:

- Matoorku ma bilaabo. Marka furaha dabka la rogo, bilow-bixiyuhu waxa uu rogaa mishiinka oo bamka shidaalka ayaa humaaya. Sababta ayaa ah in matoorka ECU, isaga oo aan helin calaamad ka timid dareemaha booska crankshaft, uusan si sax ah u soo saari karin amar: kan dhululubada si loo bilaabo iyo kan lagu furo tuubada.

- Matoorku waxa uu kululaadaa ilaa heerkul go'an oo uu istaago ama kuma bilaabo dhaxan daran. Waxaa jirta hal sabab oo keliya - microcrack ku jira dabaylaha dareeraha PKV.

Hawlgalka aan xasilloonayn ee matoorka ee habab kala duwan

Tani waxay dhacdaa marka DPKV ay wasakhaysan tahay, gaar ahaan marka biraha birta ah ama saliiddu ay galaan. Xitaa saameyn yar oo ku saabsan microcircuit magnetic ee dareenka wakhtiga ayaa isbeddelaya hawlgalkiisa, sababtoo ah miiska ayaa aad u xasaasi ah.

Joogitaanka qarxinta matoorka oo leh culeys sii kordhaya

Sababta ugu badan waa cilladda qalabka cabbiraadda, iyo sidoo kale microcrack ee dabaylaha, kaas oo leexiya inta lagu jiro gariirka, ama dildilaaca guryaha, kaas oo qoyaanku galo.

Calaamadaha garaaca mishiinka:

- ku xadgudubka jilicsanaanta habka gubashada ee isku dhafka shidaalka-hawada ee dhululubada mishiinka gubashada gudaha;

- ku boodboodka aqbalaha ama nidaamka qiiqa;

- guuldarada;

- hoos u dhac cad oo ku yimid awooda matoorka.

Awoodda matoorka oo la dhimay

Awoodda matoorka ayaa hoos u dhacda marka shidaalka iyo hawada isku dhafka ah aan la keenin waqtigii loogu talagalay. Sababta cilladu waa delamination ee shoogga nuuga iyo barokaca ee xiddiga ilig marka la eego jiidi. Awoodda matoorka sidoo kale waa la dhimay iyadoo ay ugu wacan tahay burburka dabaylaha ama guriga mitirka booska crankshaft.

Sida loo hubiyo dareemaha shaft-ga laftaadu?

Waxaad si madaxbanaan u baari kartaa caafimaadka DPKV adigoo isticmaalaya:

- ohmmeter;

- oscillograph;

- adag, isticmaalaya multimeter ah, megohmmeter, network transformer.

Waa muhiim in la ogaado

Kahor inta aan la bedelin qalabka cabbiraadda, waxaa sidoo kale lagu talinayaa in la sameeyo baaritaan dhamaystiran oo kombuyuutar ah ee matoorka gubashada gudaha. Kadibna kormeer dibadda ah ayaa la sameeyaa, kaas oo meesha ka saaraya wasakhda ama burburka farsamada. Oo kaliya ka dib markaa waxay bilaabaan inay ogaadaan qalab gaar ah.

Ku hubinta ohmmeter

Kahor intaadan sii wadin baaritaanka, dami mishiinka oo ka saar dareenka wakhtiga.

Tilmaamo tallaabo-tallaabo ah oo loogu talagalay barashada DPKV oo leh ohmmeter guriga:

- Ku rakib ohmmeter si aad u cabbirto iska caabbinta.

- Go'aami heerka caabbinta ceejinta (taabo tijaabiyaha tijaabiyaha teerminalka oo wac).

- Qiimaha la aqbali karo waa 500 ilaa 700 ohms.

Isticmaalka oscilloscope

Dareemaha booska crankshaft waxaa lagu hubiyaa matoorku ordaya.

Algorithm ee ficillada iyadoo la adeegsanayo oscilloscope:

- Ku xidh tijaabiyaha iyo saacada.

- Ku wad barnaamij kombayutarka korkiisa saaran kaas oo isha ku haya akhrinta qalabka elegtarooniga ah.

- U gudbi shay bir ah hortiisa shidma-shaft-ga dhawr jeer.

- Multimeter-ku waa OK haddii oscilloscope-ku uu ka jawaabo dhaqdhaqaaqa. Haddii aysan jirin calaamado ku yaal shaashadda PC, waxaa lagu talinayaa in la sameeyo baaritaan buuxa.

Hubin dhamaystiran

Si aad u fuliso, waa inaad:

- megohmmeter;

- transformer network;

- mitirka inductance;

- voltmeter (doorbidayaa digital).

Aasaasiga waxqabadka:

- Ka hor inta aanad bilaabin iskaanka buuxa, dareemaha waa in laga saaraa mishiinka, si fiican loo dhaqo, la qalajiyo, ka dibna la cabbiro. Waxaa lagu fuliyaa oo keliya heerkulka qolka, si ay tilmaamayaashu u noqdaan kuwo sax ah.

- Marka hore, inductance ee dareemayaasha (gariiradda inductive) ayaa la cabbiraa. Qiyaasta tirooyinka ay ku shaqaynayso waa in ay ahaataa inta u dhaxaysa 200 iyo 400 MHz. Haddii qiimuhu si weyn uga duwan yahay qiimaha la cayimay, waxay u badan tahay in shidmahu cilladaysan yahay.

- Marka xigta, waxaad u baahan tahay inaad cabbirto caabbinta dahaadhka ee u dhexeeya terminalka gariiradda. Taas awgeed, megohmmeter ayaa loo isticmaalaa, dejinta tamarta wax soo saarka ilaa 500 V. Way fiicantahay in la sameeyo habka cabbirka 2-3 jeer si loo helo xog sax ah. Qiimaha iska caabbinta dahaarka ee la qiyaasay waa in uu ahaadaa ugu yaraan 0,5 MΩ. Haddii kale, fashilka dahaarka ee gariiradda ayaa la go'aamin karaa (oo ay ku jirto suurtagalnimada wareegga gaaban ee u dhexeeya leexashada). Tani waxay muujinaysaa cilladda aaladda.

- Kadib, iyadoo la adeegsanayo isku xirka shabakada, saxanka waqtiga waa la jarayaa.

Dhibaato toogasho

Waxay macno samaynaysaa in la hagaajiyo dareemaha cilladaha sida:

- gelinta dareeraha wasakhaysan ee PKV;

- joogitaanka biyaha ee isku xirka dareemayaasha;

- dillaaca galka difaaca ee fiilooyinka ama qalabka dareemayaasha;

- isbeddelka polarity ee fiilooyinka calaamadaha;

- xidhiidh la'aan suunka;

- fiilooyinka calaamadaha gaaban ee dhulka dareenka;

- hoos u dhigista ama kordhinta nadiifinta kor u kaca ee dareeraha iyo isku xidhka saxanka.

Shaxda: ku shaqee cilladaha yaryar

| Asal ahaan | Micnaheeda |

|---|---|

| Gelitaanka gudaha dareemaha PKV iyo faddaraynta |

|

| Joogitaanka biyaha ee isku xirka dareemayaasha |

|

| Gaashaanka ama suunka dareemaha ee jabay |

|

| Dib u celi dabaylaha fiilooyinka signalada |

|

| Dareemuhu kuma xidhna suunka |

|

| Xadhkaha dareenka dareemayaasha ayaa gaabiyay dhulka |

|

| Yaraynta ama kordhinta nadiifinta korka ee dareeraha iyo saxanka isku xidhka |

|

Sidee loo beddelaa dareemaha booska crankshaft?

Nuancesyada muhiimka ah ee ay tahay in la ilaaliyo marka la bedelayo DPKV:

- Ka hor inta aan la kala saarin, waxaa lagama maarmaan ah in la isticmaalo calaamado muujinaya booska boolka ee dareenka, DPKV laftiisa, iyo sidoo kale calaamadaynta fiilooyinka iyo xiriirada korantada.

- Marka la saarayo oo la rakibayo dareeraha cusub ee PKV, waxaa lagula talinayaa in la hubiyo in saxanka waqtigu ku jiro xaalad wanaagsan.

- Ku beddel mitirka suunka iyo firmware.

Si aad u bedesho dareenka PKV, waxaad u baahan doontaa:

- Qalabka cusub ee cabbiraadda;

- tijaabiyaha tooska ah;

- godnometer;

- furaha 10.

Algorithm action

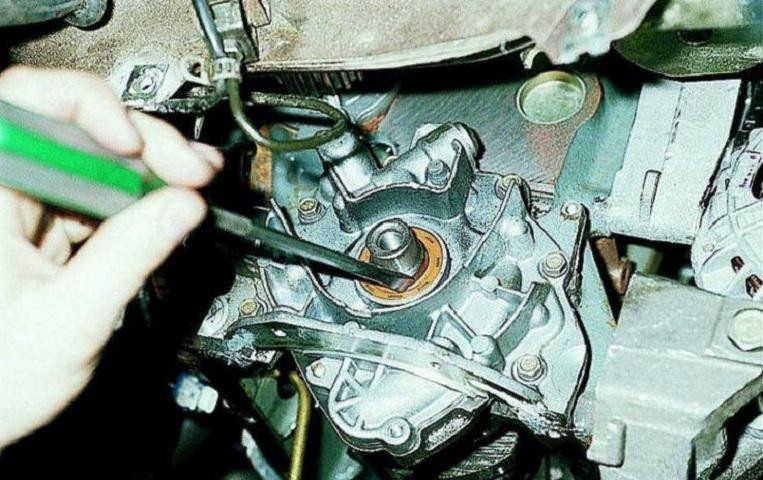

Si aad gacmahaaga u beddesho dareemaha booska crankshaft, waxaad u baahan tahay:

- Demi dabka shidan.

- De-tamar ka dhig qalabka elegtarooniga ah adiga oo ka jaraya baloogga terminalka kantaroolaha.

- Fure, fur furka hagaajinaya dareemaha, ka saar DPKV khaldan.

- Isticmaal calal si aad meesha ugu degto uga nadiifiso kaydka saliidda leh iyo wasakhda.

- Ku rakib cabbirka cadaadiska cusub adoo isticmaalaya xirmooyinki hore.

- Samee cabbirada xakamaynta farqiga u dhexeeya ilkha beddelka jiidiyaha wadista iyo xudunta dareemayaasha adoo isticmaalaya caliper vernier. Boosku waa inuu u dhigmaa qiimayaasha soo socda: 1,0 + 0,41 mm. Haddii farqiga uu ka yar yahay (ka weyn) qiimaha la cayimay inta lagu jiro cabbirka xakamaynta, booska dareenka waa in la saxo.

- Hubi iska caabinta dareemaha booska crankshaft adoo isticmaalaya is-tijaabin. Dareemaha shaqada, waa inuu ahaadaa inta u dhaxaysa 550 ilaa 750 ohms.

- Dib u deji kombayutarka safarka si aad u damiso calaamada Matoorka Hubinta.

- Ku xidh dareemaha booska crankshaft ta dhexda (xidhiidhiyaha ayaa tan loo rakibay).

- Hubi waxqabadka qalabka korantada qaabab kala duwan: nasasho iyo culeys firfircoon.